KHARE AGROMECH INDUSTRIES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KHARE AGROMECH INDUSTRIES P.LTD.

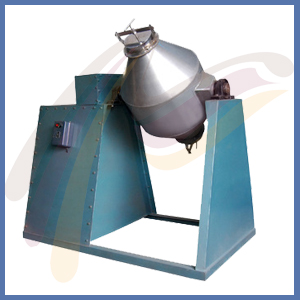

Conical Mixers

Conical Mixer is a machine with a very high degree of efficiency. It is used for mixing dry powder and granules homogeneously.

These machines are widely used in pharmaceutical industry to granulate and blend various medicated powders. The conical shape at both ends of the mixer ensures uniform mixing and easy discharge of the powder

All contact parts in Stainless steel.

Sturdy and robust construction.

Minimum maintenance cost.

Available in three phase connection which results in low electricity consumption.

100% cleanout.

Easy inlet and outlet

Uniform and even mixing without heat generation.

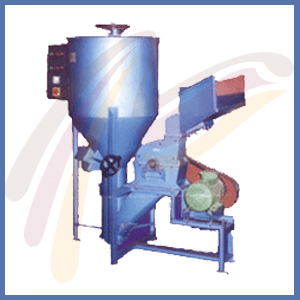

Double Shaft Mixers

W shape horizontal mixing chamber with dual shaft and multi paddles.

Dual outlet doors are specially designed for maximum clean out

Pneumatic door opening system.

Liquid spraying system at the top for blending of liquids.

Diversified applications like animal feed, Food, Spices, Pharmachemicals, Fertilizer industry etc.

CV (coefficient of variation) - <=3 depending upon the material being mixed.

MOC in various grades like SS-304, SS-316, SS316L and MS.

Sturdy and robust construction

Soft and gentle mixing without increase in temperature.

Ribbon Blenders

Ribbon Blendor is very fast and 100% efficient mixer to blend practically any dry powders, from food products to chemicals.

Even liquids in small amount can also be mixed in very efficent way.

Ribbon Blendor consist of U shape horizontal trough and specially fabricated ribbon agitator.

Ribbon agitator consist of set of inner and outer blades. The outer blades moves the matertial in one direction while inner blades move the materials in exactly opposite direction.

The Ribbon Blendor is carefully design to ensure thorough mixing with required CV ( Coefficient of variation ).

Temperature rise is also minimum which is important when we consider vitamin mixing.

Discharger get can be manual or pneumatically operated for direct filling in bags or dumping into storagebin.

Ribbon Blenders can be constructed in mild steel (MS) or Stainless Steel (SS) depending upon material to be blended.

Ribbon Blenders operates between 20 and 40rpm.

Fluid coupling can also be used as a option they are useful to start mixer on load in case of sudden electri failures.

Automatic oil or liquid spraying arrangement can be done.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.